Optical Bonding

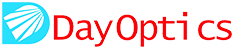

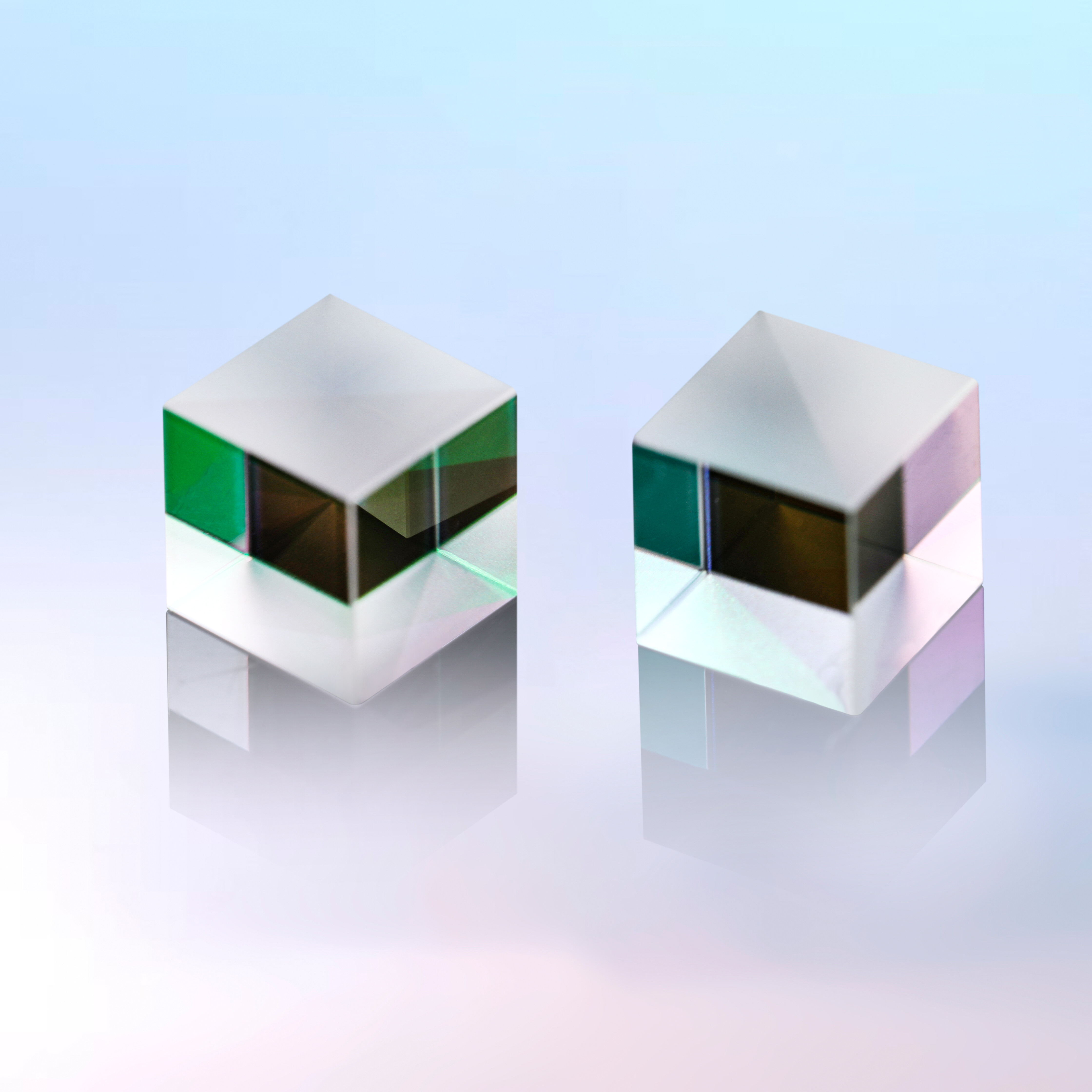

Dayoptics adopts the technology of opticalbonding for manufacturing ordinary polarization beam splitting cubes.

These beam splitters are opticallycontacted, which refers to the use of molecular gravity to achieve the adhesionbetween the two prisms, without the use any adhesive. This process involvesapplying a little pressure to make two clean, smooth, and shape-consistentoptical surfaces bond together. The reduction in friction force with smoothercontact surfaces applies within a certain range, but when the smoothnessexceeds a certain limit, the friction force increases. This happens because themolecules on the surface of the two objects are tightly adjacent to each other.

The distance between them is very small, and due to electromagnetic forcesbetween the molecules, they attract each other. The smoother the surface, thesmaller the distance between the molecules, and the greater the attraction. Asa result, it becomes difficult to separate the two parts. In the case of identical materials,such as optical glass, the pieces may even join in a way that creates a singlepiece with no discernible internal interface.

The finished product manufactured byoptical bonding exhibits exceptional strength. Separating the parts is nearlyimpossible. While the surface flatness maintains its high level of precision. Utilizingtheir unique technology, Dayoptics performs optical bonding under high temperaturein an airtight, dust-free environment. The temperature is adjusted based on thematerials involved, activating the molecules on the contacted surfaces, andenabling them to fully fuse. Subsequently, as the temperature changes, themolecular state stabilizes, resulting in a more compact structure of themolecules on the contacted surface, capable of withstanding temperaturevariations.

Due to the absence of adhesive and the specialized high-temperatureprocess, the surface of the product remains unaffected by adhesive-relatedissues, thereby improving the laser damage threshold. The binding surface canachieve a damage threshold of 15 J/cm² @ 1064 nm, 10 ns, 20 Hz, or even higher.

Optical bonding finds applications in High-PowerPBS, High-Power Waveplates, and Micro-Optics Assemblies.